Stainless steel wire rope mesh details

Stainless steel wire rope mesh

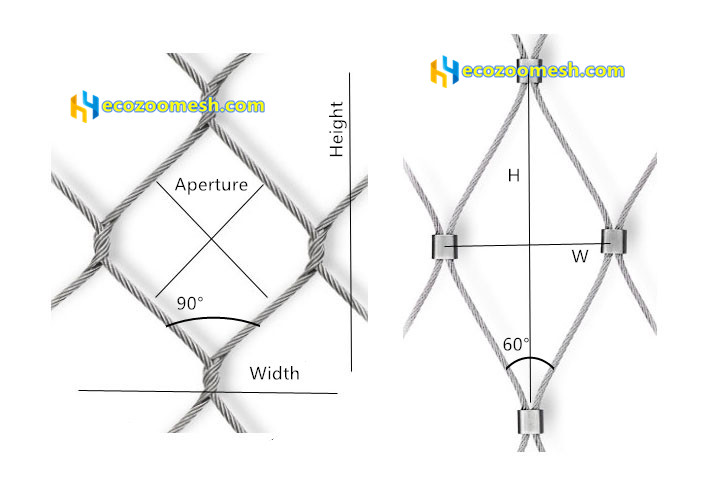

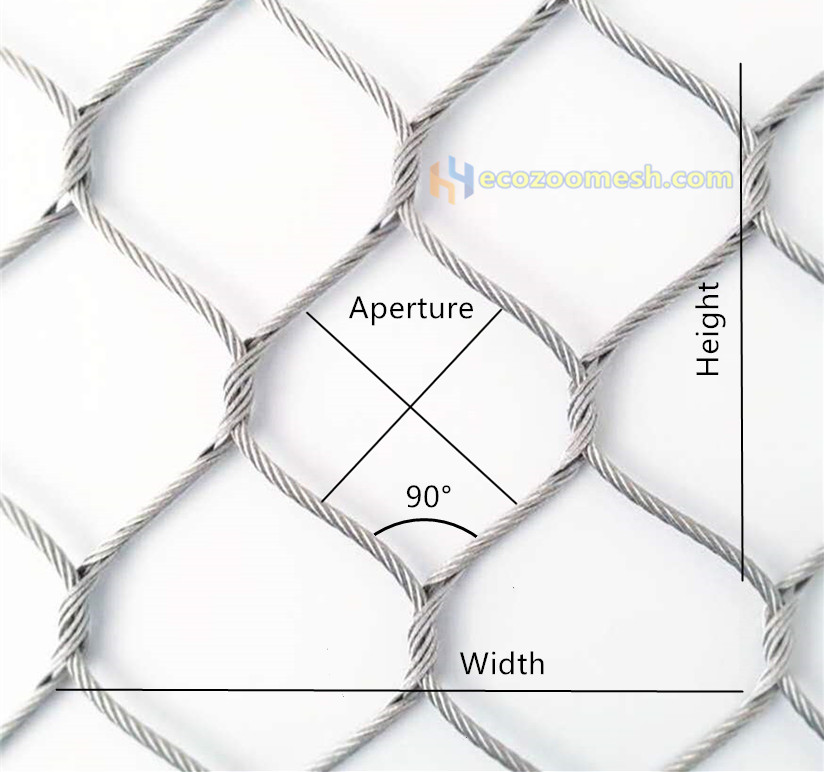

Stainless steel wire rope mesh is also called stainless steel cable mesh, wire rope woven mesh, stainless steel cable ferrule mesh, etc. It is made of 304/316 stainless steel material, which is a kind of metal mesh with special elasticity and extreme flexibility. The mesh shape is rhomboid. The common mesh hole angle is 60° and 90°. The size of the mesh aperture and the thickness of the wire cable can be customized according to different applications. It is a creative product born in the 1990s. It is durable and corrosion-resistant and fully reflects the super-toughness and plasticity of austenitic stainless steel. Once it was born, it was quickly accepted by the global market and became a building material that architects and designers favorite.

Learn more about the History of Stainless Steel Wire Cable Mesh

Hengyi Metal Ecological Mesh Co. Ltd. is a leader in the stainless steel wire rope mesh industry. We specialize in the development and production of stainless steel wire rope mesh products with more than 20 years of experience.

According to the different way of connecting stainless steel wire cables, stainless steel cable mesh are mainly divided into two types: stainless steel wire cable woven mesh and stainless steel wire cable ferrule mesh, all of which have diamond mesh.

Stainless steel wire cable woven mesh is a stainless steel wire cable twisted and crossed together, no need for additional steel ferrule, simpler structure, and lighter weight, more beautiful and more durable.

However the ferrule mesh is superior in appearance. And of course, it's no worse in terms of security. In addition to being used as animal cage netting, stainless steel cable mesh ferrule mesh is also used by many designers and artists in creative designs such as security railing and decorations.

Our company specializes in the making of stainless steel cable woven mesh and ferrule mesh. Because of its many advantages, stainless steel wire rope mesh is destined to replace other metal material for zoo animal enclosures and safety nets in the future, with a promising future.

1. The material of Stainless steel wire rope mesh

2. Color of Stainless steel wire rope mesh

3. Types of Stainless steel wire rope mesh

4. Specification of Stainless steel wire rope mesh

5. Costs and prices

6. Production cycle, packaging, freight and deliver time

1. Stainless steel wire rope mesh material

Stainless steel wire rope mesh is available in 304/304L 316/316L universal stainless steel. 304/304L and 316/316L stainless steel is a grade of stainless steel produced in accordance with American ASTM standards. They have excellent corrosion resistance, easy forming, high toughness, and safety, and are widely used in the food and medical industry equipment and machine parts that require corrosion resistance.

In order to maintain the corrosion resistance inherent in stainless steel, they contain 18% or more of chromium and 8% or more of nickel. The steel wire rope mesh made of stainless steel material is safe and reliable, corrosion-resistant, high-toughness, soft and flexible, environment-friendly, extar-long service life.

1. Naming standards of stainless steel materials

SS 304/316SS is short for Stainless Steel.

“SS304” is “Stainless Steel 304”.

AISI 304/316

Means stainless steel meets US ASTM standards.

SUS 304/316

SUS is the Japanese stainless steel grade, equivalent to AISI,

and their standards are the same.

2. Difference of stainless steel materials

Chemical Composition (%) of 304/316| Steel Grade | C | Si | Mn | P | S | Cr | Ni | Mo | others |

|---|---|---|---|---|---|---|---|---|---|

| 304 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 18.0-20.0 | 8.0-12.0 | -- | |

| 304L | ≤0.03 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 18.0-20.0 | 8.0-12.0 | -- | |

| 316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 16.0-18.0 | 10.0-14.0 | 2-3 | -- |

| 316L | ≤0.03 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 16.0-18.0 | 10.0-14.0 | 2-3 | -- |

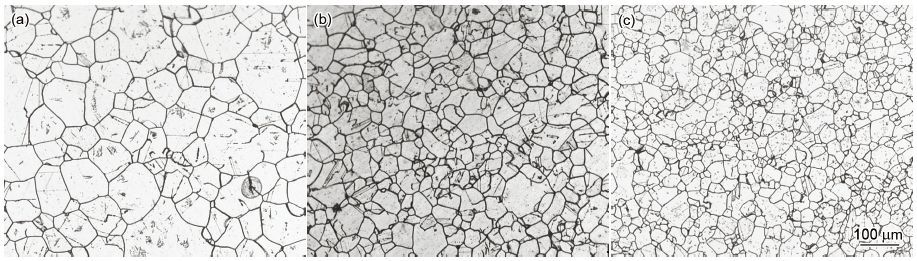

SSWRMD-Microstructure of austenitic stainless steel

Difference between 304 and 316 :

1 > Different chemical composition:

304 (Ni 8-12), 316 (Ni 10-14). 316 has a higher Ni elements content.

Mo (2-3) elements added in 316.

2 > Different properties:

304 steel has excellent mechanical properties. It has considerable corrosion resistance, high-temperature resistance, strong plasticity, and can be stamped. It is commonly used in tableware, furniture, equipment, and medical equipment.

The 316 steel increases the Ni content on the basis of 304 and increases the Mo element, which can significantly improve its acid and alkali resistance and high-temperature resistance. It is often used in the environment of acid-based solution and seawater contact and is also called marine steel. Moreover, there is a remarkable feature of 316 steel, that is, there is basically no phenomenon of thermal expansion and contraction, which is extremely important for precision parts.

Difference between 304/316 and 304L/316L:

304/316 (Carbon content 0.08) and 304L/316L (Carbon content 0.03). The main difference is the carbon content.

Lower carbon content ensures intergranular stability of materials at high temperatures, and 304L/316L is suitable for high chlorine environments, high temperature environments and where soldering is required.

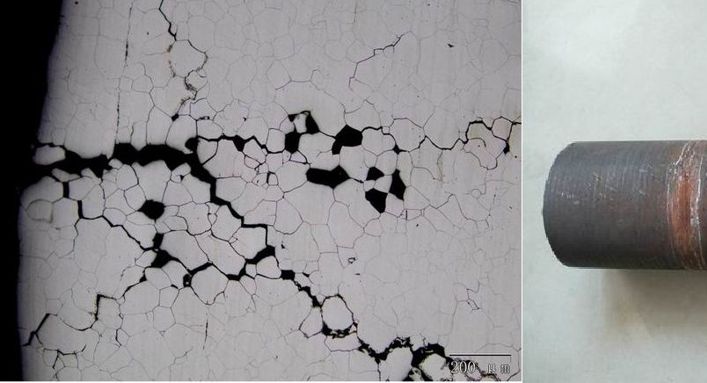

SSWRMD-Stainless steel Intergranular corrosion

The corrosion resistance of austenitic stainless steel comes from the chromium oxide protective layer formed on the metal surface. If the material is heated to a high temperature of 450 ° C to 900 ° C or in a high chlorine environment, the structure of the material changes, and chromium carbide is formed along the edge of the crystal. Thus, a chromium oxide protective layer cannot be formed at the edge of the crystal, resulting in a decrease in corrosion resistance. This type of corrosion is called "intergranular corrosion."

This resulted in the development of 304L and 316L stainless steel to combat this corrosion. Both 304L and 316L stainless steel have lower carbon content.Because of the reduced carbon content, chromium carbide is not produced and no intergranular corrosion occurs.

2. Color of Stainless steel wire rope mesh

Dyeing of stainless steel wire rope mesh

After years of research and development investment by Hengyi Metal Mesh, the stainless steel wire rope mesh dyeing process is now mature.

Our company adopts the chemical oxidation coloring method to form an oxide film on the surface of the stainless steel wire rope mesh, which can protect the stainless steel material while forming different colors and is more resistant to corrosion, heat and ultraviolet rays. The color dyed by this process is uniform and bright in color, not fade, and not fall off, much better than paint coating and electroplating.

According to reports, "Austenitic stainless steel is colored by oxidation, exposed to the industrial atmosphere for 6 years, exposed to the maritime atmosphere for 1 year and a half, soaked in boiling water for 28 days, or heated to about 300 ° C, and its color luster no change."

The currently available colors are: Natural, and Black.

- SSRM1- stainless steel wire rope

- SSRM2- Stainless steel wire rope diameter

- SSRM3- colors of stainless steel rope details

- SSRM4- natural stainless steel cable mesh details

- SSRM5- black stainless steel rope mesh details

- SSRM6- stainless steel ferrule mesh details

- SSRM7- plain stainless steel rope mesh package

- SSRM8- black stainless steel rope mesh package

- SSRM9- stainless steel rope ferrule mesh package

3. Stainless steel wire rope mesh types

Stainless steel wire rope mesh is including two types:

1> Stainless steel cable woven mesh (stainless steel sleeveless wire rope mesh)

2>Stainless steel cable ferrule mesh (stainless steel sleeved wire rope mesh).

We can judge that the two types of mesh are composed of stainless steel wire cables from the names, but the processing technology is different. The mesh knot (grid) is fixed in different ways.

The application of these two types of cable mesh nets is very similar, and can be used as the zoo fence mesh, aviary mesh, animal enclosures, zoo enclosure fence, safety net, and railing net.

What is the difference between stainless steel rope woven mesh and stainless steel ferrule mesh?

- The rope woven mesh structure is simpler, has higher light transmission, and has better transparency effect on visual effects. It is easier to be ignored by people and has little effect on people's vision. Watching at a distance is almost invisible. The stainless steel wire rope mesh benefits from its simple structure, its mesh is more firm and will not deform. From the perspective of product quality, the wire rope woven mesh has a very stable product quality.

- Another difference between a rope woven mesh and a ferrule mesh is the difference in weight. The same area, the same thickness of the wire rope, the woven mesh and the ferrule mesh weight are different. Because the ferrule mesh is fixed by the steel ferrule, the unit weight is heavier. That is, under the same order quantity, the cable woven mesh is lighter.

- The last difference is that the mesh aperture. Wire rope ferrule mesh is typically stretched to 60 degrees when installed. The aperture of the mesh is based on its diagonal not legs.

PAGE•Differences between woven mesh and ferrule mesh?

4. Specification of Stainless steel wire rope mesh

Stainless steel wire rope mesh is a multipurpose net for various venues, according to the thickness of the wire rope and the size of the mesh to divide the formation of a very large number of product specifications.

You can customize the specifications of the mesh you need. Thanks to the processing method, the size of our products, single mesh panel can also be customized, up to 3000 square feet of one piece.

Stainless-steel-rope-mesh-structure

Compared to other products, oversized single mesh panel can form better visual effects while reducing installation steps and difficulties.

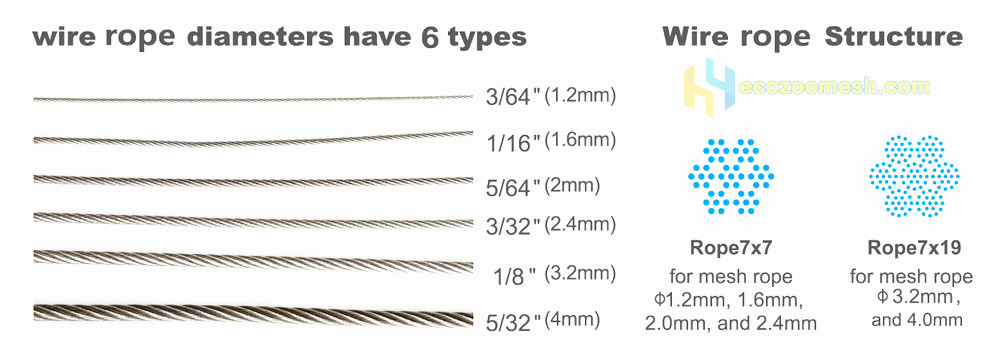

The wire rope diameter that can be selected are:

3/64", 1/16", 5/64", 3/32", 1/8".

The mesh size that can be selected are:

0.8", 1", 1.2", 1.5", 2", 2.4", 3", 3.6", 4", 5", 6".

How the specification is named: Please see the details of the specific specifications

It is usually more intuitive to classify according to the different rope diameters. The diameter of the wire rope determines the maximum force value of the single wire rope in the mesh.

It is critical to determine the thickness of the wire rope according to the usage scenario. The size of the mesh is determined by the purpose of the mesh erection, for example, to keep animals in captivity, or to stop animals.

The size of the wire cable mesh aperture is determined by the size of the animal or object being worked on.

3/64" diameter and 1/16" are both commonly used in small birds, large birds aviary and small animals, for example parrots aviary mesh.

5/64" and 3/32" diameter can be used in some medium-sized animals or large birds.

1/8" diameter can be used in large animals including big cats, bears, and big primates.

PAGE1•Form of Specification Details

PAGE2•How to choose the mesh aperture?

PAGE3•How to determine the rope diameter of the wire mesh?

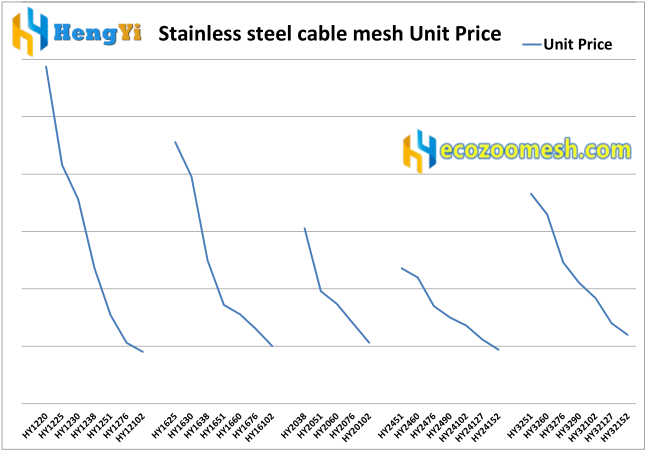

5. Costs and prices

The price of stainless steel wire rope mesh is often of great concern to the buyer.

stainless steel cable mesh unit price 4

1. First, different specifications of different prices, which is also the biggest factor affecting the unit price.

2. The prices of freight according to the mode of transport, the route and the weight of the goods are different.

Usually, according to the low to high freight rate, the transportation methods are sea, air, and express.

3. Real-time changes in exchange rates can also affect prices, so you need a real-time RFQ to get the latest price.

4. Precise mesh panel size with the most appropriate specifications can reduce your costs effectively.

Hengyi Metal Mesh can provide you with the most favorable ex-factory price.

Dowload:Stainless-steel-cable-mesh-Unit-Price.pdf

6. Production cycle, packaging, freight and deliver time

>Size of Flexible Wire Mesh RollThe size of the bulk roll varies depending on the size of the rope mesh ordered.

>Order and deliver time

The order could be arranged within 24hours, lead time is between 7-30 days depending on the quantum of order.

>Packing

The flexible wire rope mesh will be rolled and packed into the P.P. woven bags or pallets.

>Transportation

We can provide Courier, Air and Sea transportation according to your request

>Free Sample:

Sample of less than 0.5 square meter stainless steel cable mesh is provided free of charge. Requestor needs to incur the courier charges..